Types of Industrial Ventilation: Your Ultimate Guide to a Safer and Healthier Workspace

Here at Rolltech Australia, we understand that industrial ventilation is far more than a mere regulatory requirement; it’s a cornerstone for ensuring a safe and healthy work environment across a myriad of industries.

In this ultimate guide, we’ll delve deeper into the different types of industrial ventilation systems that are commonly employed. Understanding these systems is beneficial and essential for employers and employees.

It enables informed decisions that lead to optimal air quality, reduced operational costs, and effective prevention of occupational hazards.

General Ventilation Systems

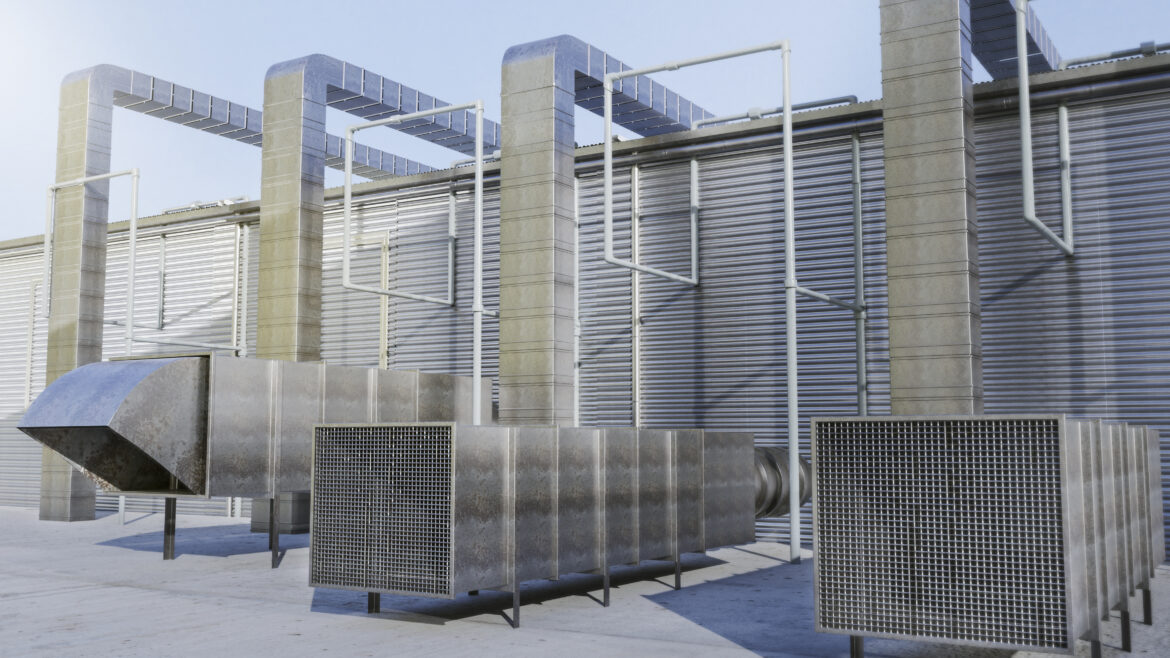

General ventilation serves as the foundational layer of industrial ventilation. It is designed to circulate air throughout an entire workspace and ensures that fresh air replaces stale or contaminated air.

The system typically comprises large fans, ducts, and filters that work in tandem to distribute air evenly. Fans pull in fresh air, ducts channel it throughout the facility, and filters purify it before circulation.

The system typically comprises large fans, ducts, and filters that work in tandem to distribute air evenly. Fans pull in fresh air, ducts channel it throughout the facility, and filters purify it before circulation.

Opting for general ventilation offers several advantages, such as uniform air distribution, which reduces “dead zones” where contaminants can accumulate. Additionally, these systems are often more cost-effective in installation and maintenance than specialised systems.

Their versatility makes them suitable for a wide range of industrial settings, from manufacturing plants to warehouses.

Local Exhaust Ventilation Systems

Local exhaust ventilation systems are specifically designed to capture and remove airborne contaminants at their source before they disperse into the general workspace. The system usually consists of a capture hood, which serves as the entry point where contaminated air is drawn in.

Ductwork then channels this captured air towards a filtration unit, which cleans the air before it’s either expelled or recirculated.

These systems are particularly effective in chemical plants for capturing fumes and vapours, welding stations for capturing metal fumes, and paint shops for efficiently removing volatile organic compounds (VOCs).

Dilution Ventilation Systems

Dilution ventilation aims to reduce the concentration of airborne contaminants by mixing contaminated air with clean, fresh air. The system draws in fresh air from the outside or from less contaminated areas within the facility.

This fresh air then mixes with the contaminated air, diluting the concentration of pollutants before it is expelled, usually through roof vents. While these systems are relatively easy to install and maintain, they are less effective for highly toxic or concentrated substances.

Makeup Air Systems

Makeup air systems are vital for replacing the air that has been exhausted by other ventilation systems, ensuring a balanced and comfortable indoor environment. These systems come in two types: direct-fired and indirect-fired. Direct-fired systems heat air directly and offer high efficiency but require careful monitoring.

Indirect-fired systems are generally safer but less efficient, as they heat air indirectly. When choosing a makeup air system, it’s important to assess the volume and speed of air that needs replacing and consider long-term operational costs, including energy consumption.

Combination Ventilation Systems

Combination ventilation systems integrate general and local exhaust ventilation features, offering a versatile solution that can be customised to meet specific industrial needs. However, the design and maintenance of these systems can be more complex and costly.

They are particularly beneficial in manufacturing settings where different contaminants are produced and in food processing where temperature and airborne particles need to be controlled.

Conclusion

Industrial ventilation is an irreplaceable component of workplace safety, a fact we at Rolltech Australia take very seriously. It protects employees from harmful airborne contaminants and contributes to a more comfortable and productive work environment.

By understanding the intricacies of different types of industrial ventilation systems, employers can make well-informed decisions that are tailored to their industry’s specific needs, thereby ensuring the well-being of their workforce.

Frequently Asked Questions

What are the legal requirements for industrial ventilation?

Legal requirements vary by jurisdiction but generally involve adhering to occupational safety and health standards. In Australia, guidelines from Safe Work Australia are commonly followed.

What is the most cost-effective industrial ventilation system?

General Ventilation Systems are often the most cost-effective due to their simpler design and lower maintenance costs.

How often should these systems be maintained?

Filters should generally be checked and replaced every 3-6 months, and a full system check should be conducted annually.